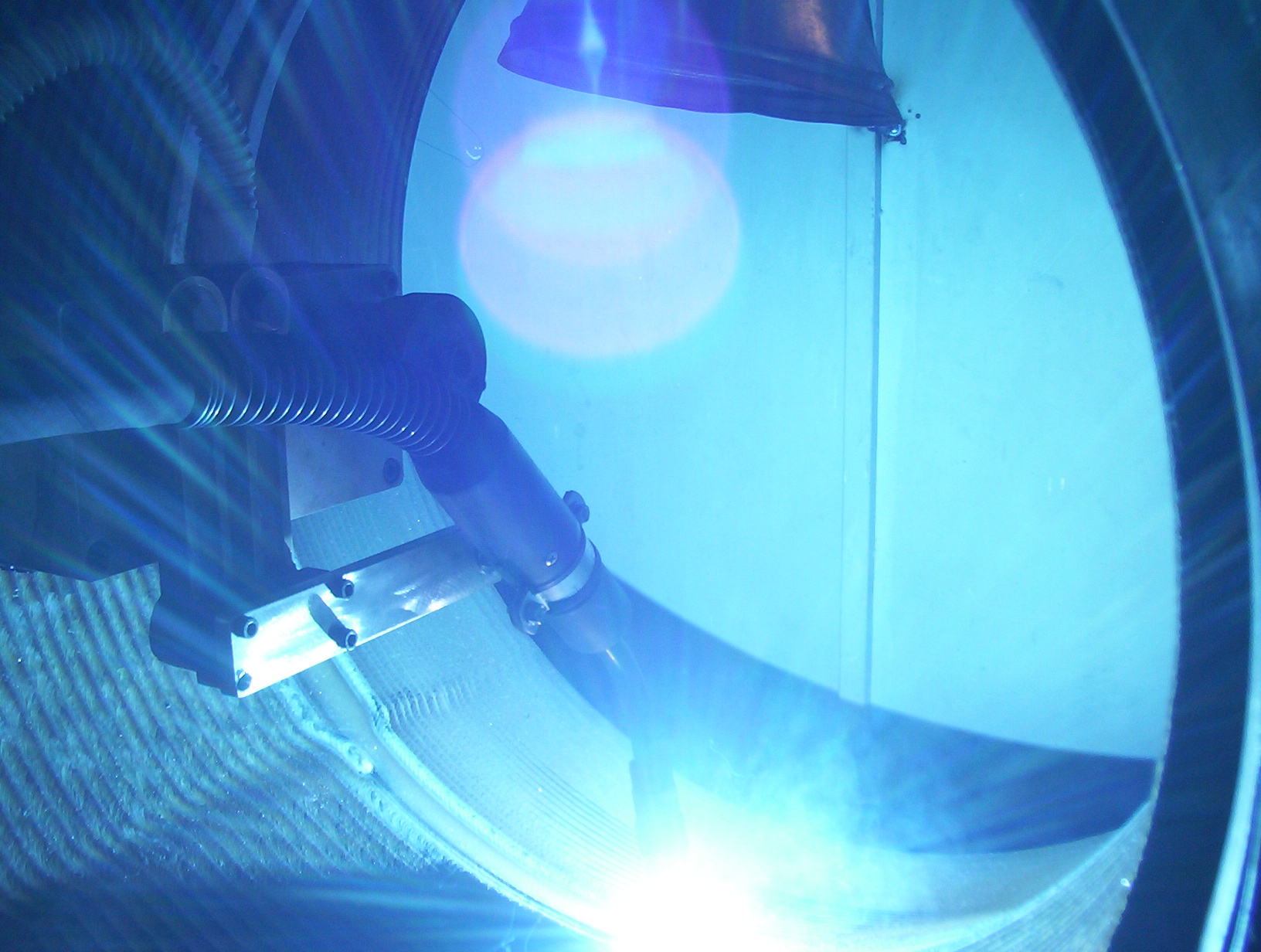

The company was born from the experiences of partners and collaborators in the construction and welding of pressure equipment, the mission of OGC is to provide customers with a product made in a workmanlike manner and complete with certifications relating to the controls carried out on the product itself.

OGC is in fact able to offer products and/or welding support with procedures (P.Q.R.) and qualified welders (W.P.Q.) according to ASME or EN standards, certified by internationally recognized entities such as Bureau.Veritas, TUV, IIS.

Here are some of the materials we commonly weld:

– CARBON STEEL (also for low temperatures)

– BASSOLEGATI with Cr-Mo (P5-P9-P11; P22…)

– AUSTENITIC STAINLESS STEEL (304; 316; 321…)

– DUPLEX, SUPERDU-PLEX

– NICKEL LEAVES (Inconel; Hastelloy, Monel)

– COPPER LEAVES (Cuproni-chel.)

– ALUMINIUM and its ALLOYS.

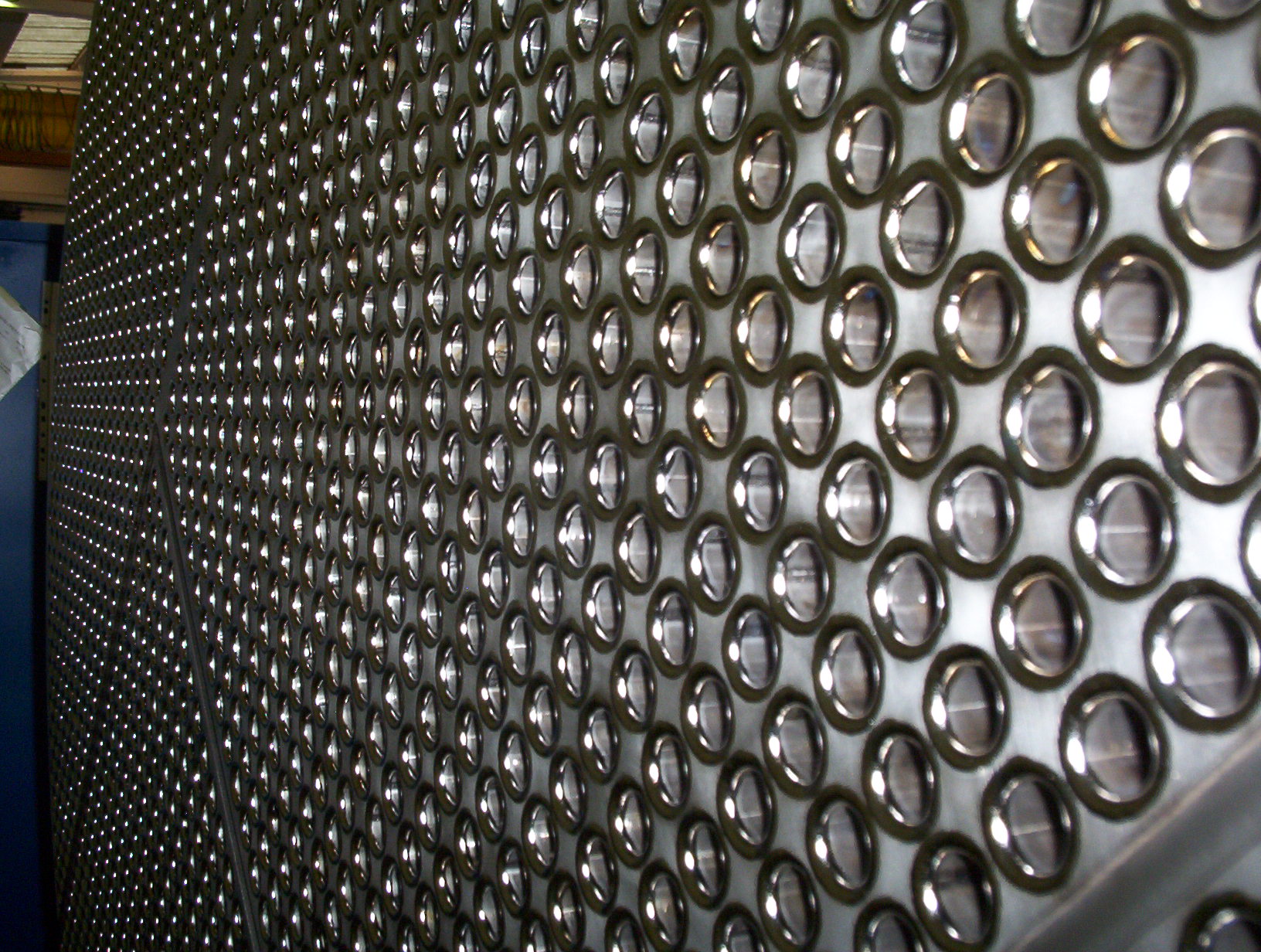

OGC. has in its staff operators of LIV.II qualified EN473 / SNT-TC 1A able to perform Non Destructive Testing (NDT) such as:

– Magnetoscopy (MT);

– Ultrasound (UT);

– Penetrating liquids (LP);

– Visual dimensional checks (VT)

We also make use of the advice of Liv.III experts and laboratories equipped to perform destructive and non-destructive tests.